Swing-Out & Pull-Back

Easy Access

Få snabb tillgång till din fläkt för enkel rengöring och maximal effektivitet.

Produktionsavbrott är alltid mycket kostsamt, så all nödvändig rengöring av en fläkt bör självklart genomföras så snabbt som möjligt. Snabb åtkomst till pumphjulet och husets interiör är oerhört viktigt i detta sammanhang. Reitz tillhandahåller lämpliga lösningar för varje sektor med sina Swing-Out och Pull-Back designvarianter, vilket minimerar stilleståndstiderna i ditt system.

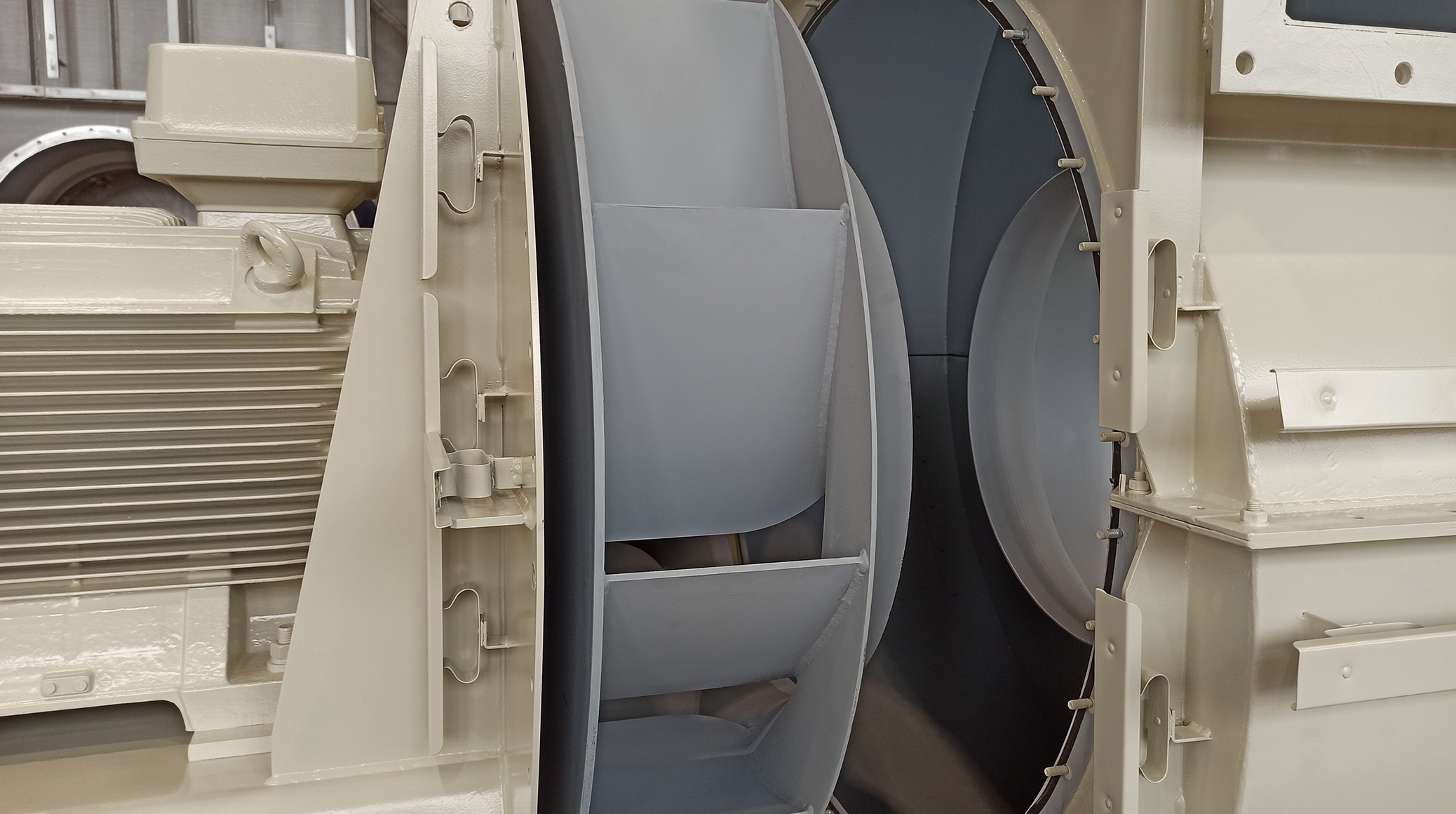

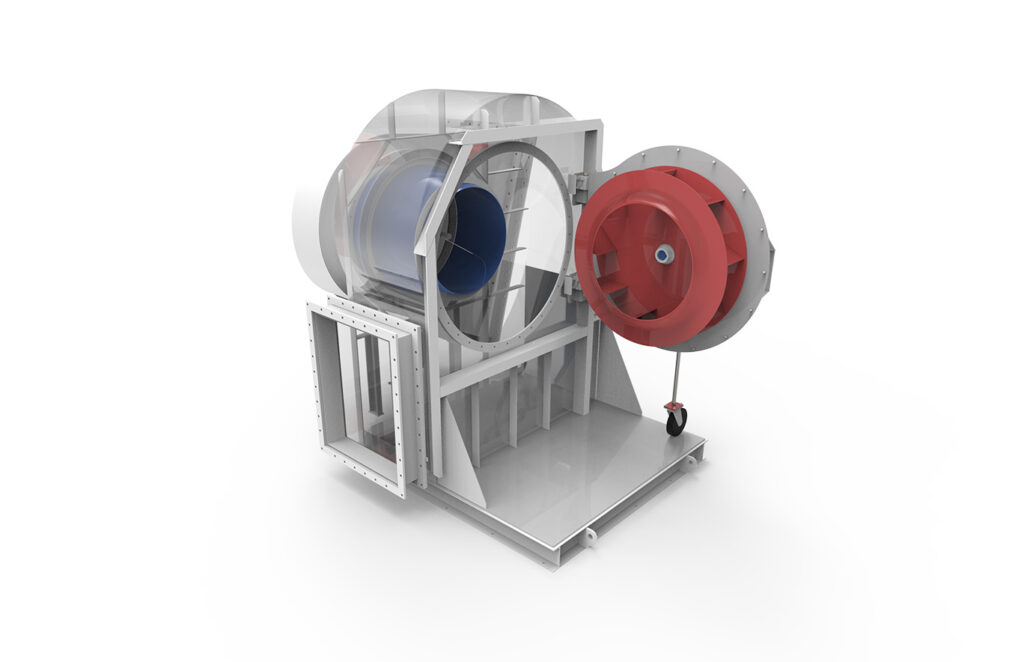

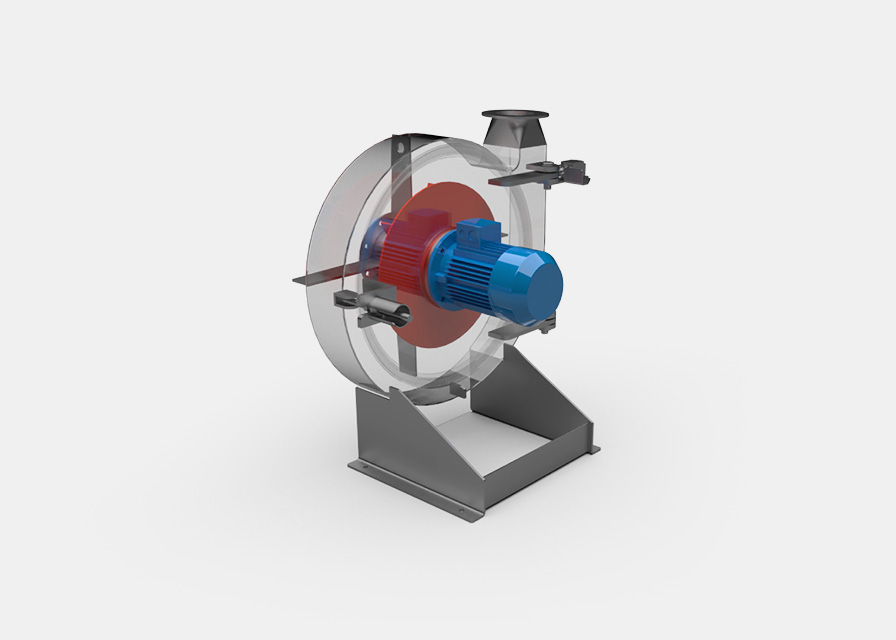

Swing-Out

Drivenheten och fläkthjulet är monterade direkt på locket i MSE-utförande. Att kunna svänga det gångjärnsförsedda locket ger fri åtkomst till fläkthjulet och fläkthusets insida.

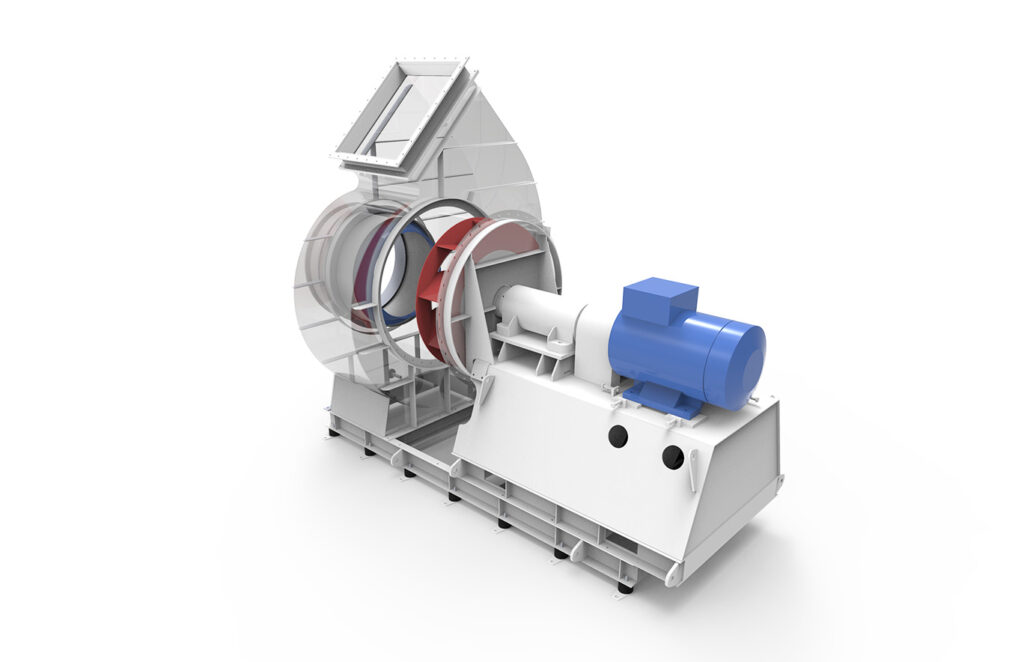

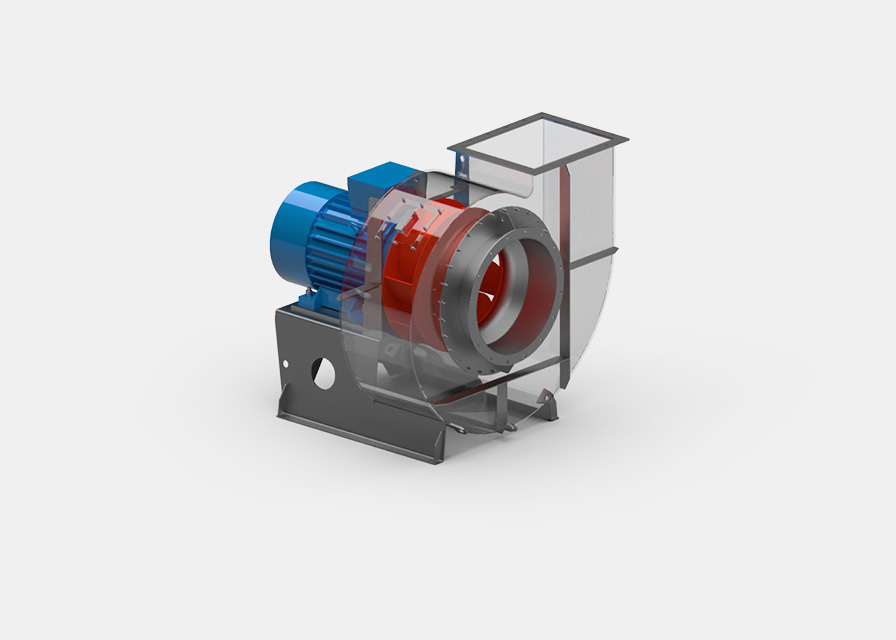

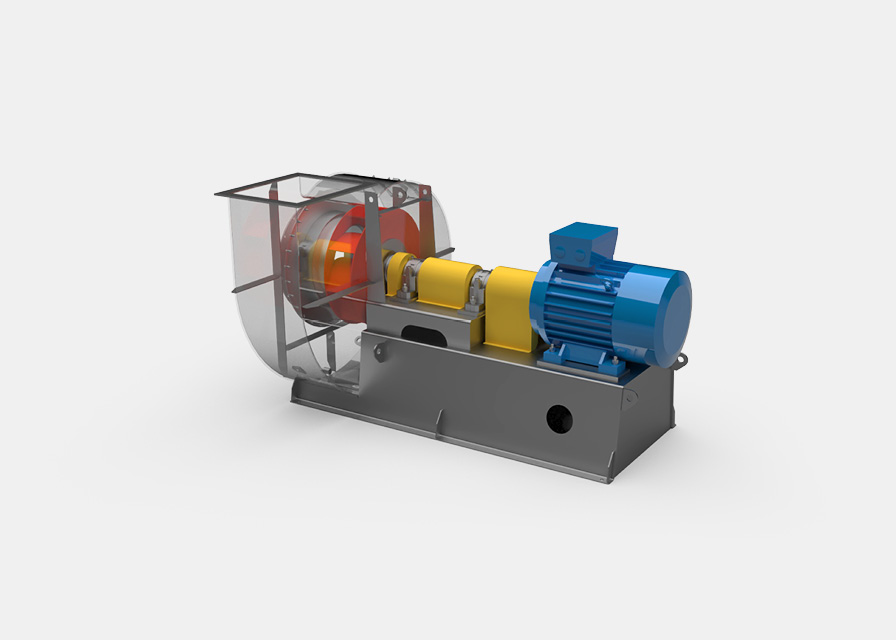

Pull-Back

MXE- och KXE-designerna kan utrustas med Pull-Back-varianten. Bestående av fläkthjul och drivning kan denna inskjutningsenhet flyttas ut ur fläkthuset. Sockeln, som glider på ramen, dras bakåt för detta ändamål.

Fördelar i korthet

Enkelt underhåll: Snabb och okomplicerad åtkomst till fläkthjul och fläkthus utan demontering av ytterligare komponenter.

Minskade stilleståndstider: Effektivt fläkthjulsbyte och minimerade produktionsstopp genom snabb underhållsprocess.

Kostnadseffektivitet: Mindre demonteringsarbete, lägre arbets- och reservdelskostnader på grund av underlättat underhåll.

Ökad produktionstillgänglighet: Snabbare underhåll och minskade stilleståndstider ökar drifttiden och tillgängligheten för systemet.

Optimerad design: Minskning av onödiga komponenter och ytor som kräver tätning för en mer utrymmesbesparande och säkrare design.

| Prestandaparametrar | min. | max. | |

|---|---|---|---|

| Δpt | daPa | 100 | 3.150 |

| V | m³/min | 5 | 2.000 |

| n | U/min | 1.000 | 3.600 |

| PMot | kW | 1,1 | 355 |

| t | °C | -20 | +300 |

Designvarianter

- ATEX

- Slitskydd

- Korrosionsskydd

- Tryckstötsäker

- Vätsketät, Dammtät

- Hygienisk design

| Prestandaparametrar | min. | max. | |

|---|---|---|---|

| Δpt | daPa | 125 | 3.150 |

| V | m³/min | 5 | 6.300 |

| n | U/min | 1.000 | 3.600 |

| PMot | kW | 1,1 | 1.500 |

| t | °C | -20 | +500 |

Designvarianter

- ATEX

- Slitskydd

- Korrosionsskydd

- Tryckstötsäker

- Vätsketät, Dammtät

- Gastät

- Hygienisk design

| Prestandaparametrar | min. | max. | |

|---|---|---|---|

| Δpt | daPa | 160 | 1.250 |

| V | m³/min | 9 | 100 |

| n | U/min | 1.500 | 3.600 |

| PMot | kW | 2,2 | 45 |

| t | °C | -20 | +80 |

Designvarianter

- Slitskydd

- Vätsketät, Dammtät