OVERVIEW OF CERTIFICATIONS

Quality management system DIN 9001 : 2015

→ REITZ Holding GmbH & Co. KG

Energy management system DIN EN ISO 50001 : 2018

→ Konrad Reitz Ventilatoren GmbH & Co. KG

Environment management system DIN EN ISO 14001 : 2015

→ Konrad Reitz Ventilatoren GmbH & Co. KG

→ REITZ India Ltd.

Management system ISO 45001 : 2018

→ Konrad Reitz Ventilatoren GmbH & Co. KG

→ REITZ India Ltd.

Welding technology DIN EN ISO 3834-2

→ Konrad Reitz Ventilatoren GmbH & Co. KG

→ REITZ India Ltd.

→ REITZ Fans (Suzhou) Co. Ltd.

Quality management for potentially explosive atmospheres pursuant to DIN EN DIN EN ISO/IEC 80079-34

→ Konrad Reitz Ventilatoren GmbH & Co. KG

Safety Certificate Contraktors (SCC**)

→ REITZ Retrofit GmbH & Co. KG

→ EAC TR CU 010

→ EAC TR CU 012/2011 (ATEX)

Individual personal Certifications:

Non-destructive testing (DIN EN 473 / ISO 9712)

Penetration testing level 2

Visual inspection level 2

IIW International Institute of Welding –

welding engineer certificate

Health, safety and environmental protection certificat

SYSTEMATIC RELIABILITY

The same quality standards which apply to production at our headquarters in Höxter also apply to our production facilities in India and China. Based on a high degree of vertical integration and certified quality management, we leave nothing to chance to impress our customers with durable fan technology.

Materials tailored to applications

First-class product quality begins with the careful selection of materials by our specialists for standard and special materials.

Certified production

REITZ customers value quality workmanship documented through certified quality management pursuant to DIN ISO 9001 and other certificates (welding, non-destructive testing, safety, environment, health and many more).

Endurance tests

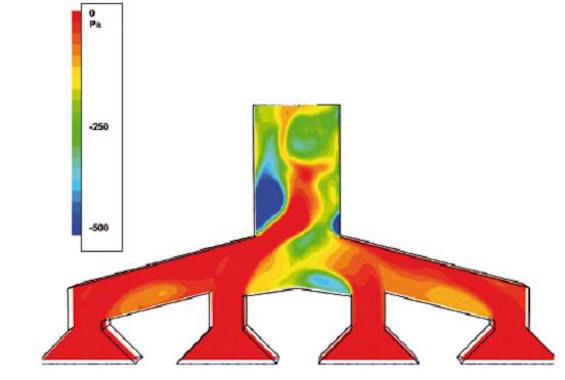

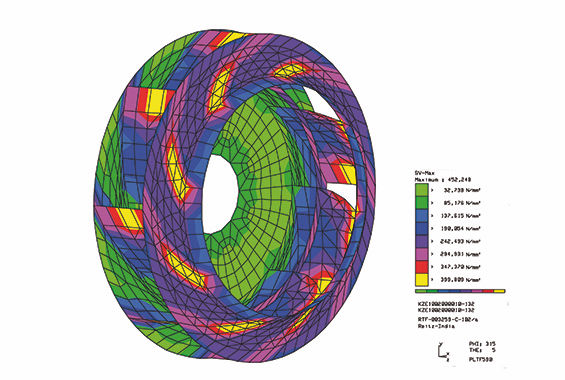

No REITZ fan leaves production without being thoroughly inspected through a number of measures (balancing of impellers in two planes for running smoothness and durability, finite element calculation to check tension in dynamically stressed components, non-destructive crack testing using a dye penetration test, vibration analysis).

Power measurement

Sizes up to 400 kW can be reliably inspected and measured on our own test bench at our headquarters in Höxter.